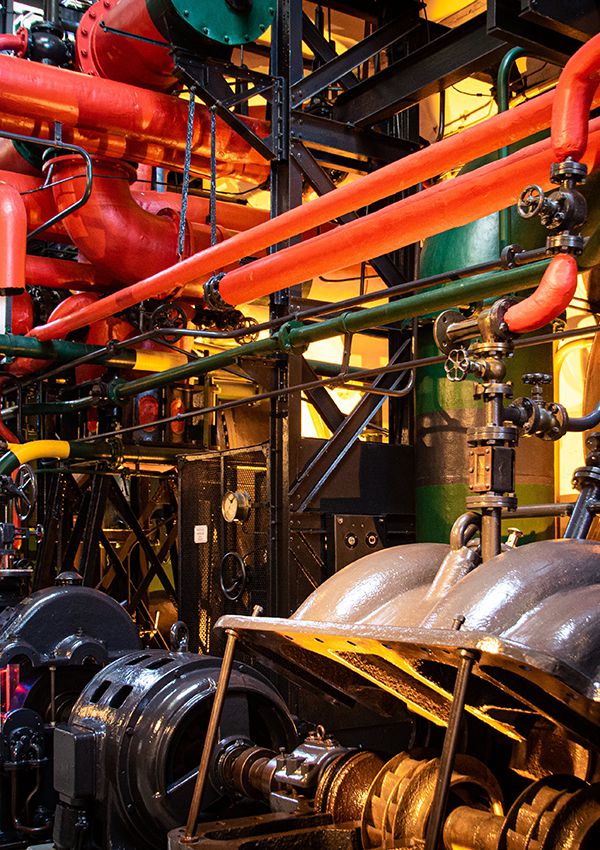

Grooved Pipe Fittings for Food & Beverage Plant

Market Application Features of Grooved Pipe Fittings for Food & Beverage Plant

For water supply and drainage systems, grooved pipe fittings offer the advantage of rapid installation without the need for welding. This not only reduces construction time and cost but also provides convenient options for replacement.

In the food and beverage industry, where maintaining a sterile production environment and ensuring hygiene are crucial, traditional pipe connector manufacturers face significant challenges in terms of regular cleaning and maintenance. The use of traditional welding or flange connections further complicates the maintenance process.

Our grooved fittings bring several advantages to food and beverage plants

- Grooved connections allow for quick and easy installation by simply fastening bolts, ensuring a seamless connection that meets hygiene requirements with ease.

- Grooved connections can be used to connect pipes made of different materials, including carbon steel and stainless steel, accommodating diverse needs in food processing facilities.

- In food processing plants where various pipe diameters are present, grooved connections can effectively address the issue of inconsistent pipe sizes.

- Grooved pipe fittings can meet the requirements of regular cleaning or replacement of pipes, which is essential in food processing facilities to maintain hygiene standards.

Recommended Pipe Couplings & Fittings

-

View More

View More- Grooved One-Stop Coupling Grooved one-stop coupling is a type of rigid quick-change pipe fitting. With a unique structural design, it eliminates the need to disassemble bolts, nuts, and gasket during installation.

-

Available sizes: 1~12 inch |DN25~DN300

-

Working pressure: 300 PSI

-

Certificate: FM/UL/CE certified

-

-

View More

View More- Grooved Concentric Reducer Grooved concentric reducers are cone-shaped pipe fittings with grooved connections that reduce the size of a pipeline in a symmetrical and concentric manner, while keeping the centerlines of the two pipes aligned.

-

Available sizes: 1 1/4×1 inch~12×10 inch |DN32×25~DN300×250

-

Working pressure: 300 PSI

-

Certificate: FM/UL/CE certified

-

-

View More

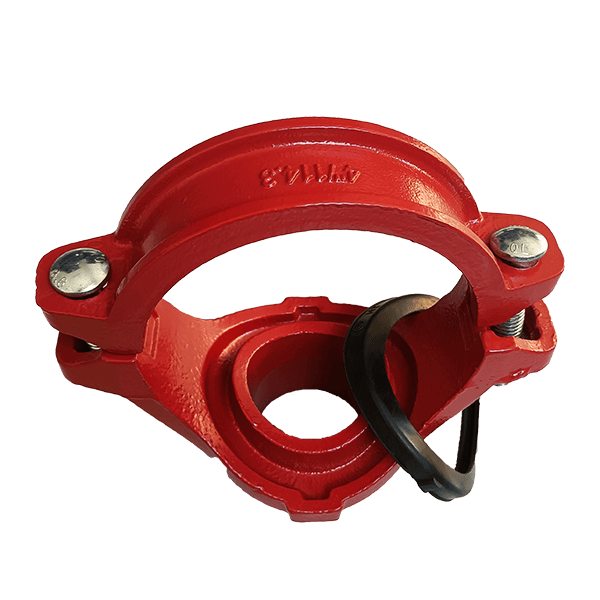

View More- Mechanical Tee Grooved Outlet Mechanical tee grooved outlet consist of upper and lower plates, a gasket, and bolts/nuts, providing a simple and fast method for branch connection.

-

Available sizes: 2×1 inch~10×4 inch |DN50×25~DN250×65

-

Working pressure: 300 PSI

-

Certificate: FM/UL/CE certified

-

-

View More

View More- Grooved Equal Tee The grooved ends are connected to the pipe using couplings for fluid distribution to provide the change in direction, and adapt sizes or components.

-

Available sizes: 1 inch~12 inch |DN25~DN300

-

Working pressure: 300 PSI

-

Certificate: FM/UL/CE certified

-

-

View More

View More- Grooved Equal Cross Grooved equal cross features convenient and quick connections utilizing a coupling. Simply insert the pipe into the coupling and tighten the bolts.

-

Available sizes: 2 inch~8 inch |DN50~DN200

-

Working pressure: 300 PSI

-

Certificate: FM/UL/CE certified

-

-

View More

View More- Grooved 90° Elbow Grooved 90°elbow is an elbow fitting that is used for connecting two pipes with the same size to make the pipeline turn 90 degrees. It provides a change in flow direction and facilitates the adaptation of sizes or components.

-

Available sizes: 1 1/4×1 inch~8×6 inch |DN32×25~DN200×150

-

Working pressure: 300 PSI

-

Certificate: FM/UL/CE certified

-

-

View More

View More- Grooved Adaptor Flange A grooved adaptor flange is an adjustable connecting flange that functions similarly to an expansion joint. It consists of two flange discs that are individually fixed, with a flange gasket placed between them.

-

Available sizes: 1 inch~12 inch |DN25~DN300

-

Working pressure: 300 PSI

-

Certificate: FM/UL/CE certified

-

-

View More

View More- Grooved End Cap A grooved end cap is specifically designed to be fitted onto the end of a pipe using a grooved connection. It serves as an isolation or cutoff device to block the pipeline and form liquid or gas tight seal.

-

Available sizes: 1 inch~12 inch |DN25~DN600

-

Working pressure: 300 PSI

-

Certificate: FM/UL/CE certified

-